101 Guide on duckbill check valve operation

Duckbill check valves are unique, one-piece, elastomeric components that act as backflow prevention devices. In 2022, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

Duckbill Check Valves are designed to provide outstanding back-flow prevention; eliminating costly and unwanted backflow from rivers, oceans, storm water, and is an excellent choice for sewage diffuser systems.

Guide on duckbill check valve operation

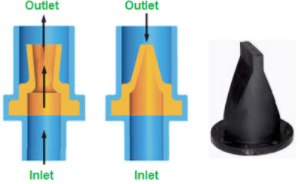

- The principal of operation is simple. Upstream pressure in the valve forces the lips or “duckbill” apart to allow flow.

- As the pressure or flow rate increases, the valve lip opens further to allow more flow. This feature allows unobstructed passage of solids at low pressure loss.

- When the pressure disappears (back pressure or backflow), the duckbill end returns to its flat shape, preventing backflow.

- Even with some wear, the “duckbill” check sleeve will still function, including sealing entrapped solids.

- The duckbill check valve is similar in function to the mitral valve in the heart.

Video Source: Youtube of Proco Products, Inc.

FOCALVALVE is a leading check valve manufacturer and supplier designing cost effective check valves。 If you want to know more about duckbill check valves, you can contact our experts directly.

Related Posts

-

Has the price of duckbill valves in China increased or decreased in 2025?

-

Why Italian Industries Trust Chinese Duckbill Valves

-

How Duckbill Valves Reduce Energy Costs by 15-30% in Industrial Systems

-

Prominent Duckbill Valve Manufacturers in 2025

-

Industrial Duckbill Valve Pricing: Key Factors and Market Overview

Leave a Message

Jack

Hi, I’m the author of this post, and I have been in this field for more than 10 years. If you want to get more info about duckbill check valves or others industrial valves, feel free to ask me any questions.